Diesel Performance Upgrades: Unlocking Maximum Power for Duramax, Cummins, and Powerstroke Engines

|

|

Time to read 13 min

|

|

Time to read 13 min

One of the most exciting aspects of owning a turbo-diesel truck—whether powered by a Duramax, Cummins, or Power Stroke engine—is tapping into its remarkable aftermarket upgrade potential. These diesel powerhouses come engineered with ample strength from the factory, ready to unleash significantly more performance with just a few carefully selected modifications.

Whether your goal is enhanced towing capability, street-ready horsepower, or competitive performance builds, upgrading your diesel engine can transform your truck into a more powerful, reliable, and enjoyable machine.

Here's how to unlock that hidden potential and make the most out of your Duramax, Cummins, or Power Stroke engine.

Ready to transform your diesel truck into the ultimate machine? Whether you’re focused on towing heavy loads, dominating the street, or just making your daily drive better, choosing the right upgrades can elevate your Duramax, Cummins, or Power Stroke engine to new heights.

Below, we’ve curated the essential performance upgrades that diesel enthusiasts rely on to maximize horsepower, torque, dependability and overall drivability, helping you unlock the full potential of your diesel-powered truck.

The quickest and most dramatic performance upgrade is ECU tuning—also called remapping or reprogramming. Since all modern diesel engines are controlled by complex engine management systems, factory tunes are conservative by design, focusing on emissions and drivetrain longevity.

With a reputable tuner or programmer, you can unlock substantial gains:

Power Gains:

+50 to 150+ hp and massive torque increases

Examples:

A mild tune on a Duramax L5P or Power Stroke 6.7L can take output from 470 hp to 550+ hp, and torque from 975 lb-ft to well over 1,100 lb-ft

Cummins Advantage:

Older Cummins ECMs (especially 5.9L and early 6.7L) are especially tuner-friendly and offer straightforward access to additional torque with minimal hardware changes

Supporting Components Matter:

Tuning increases stress on drivetrain parts—especially torque converters, clutches, and head gaskets

Recommended Safety Mods:

Transmission tuning or upgraded valve bodies

Head studs (especially on high-torque Cummins builds)

High-flow intake and exhaust systems

Driveability:

Tuned diesels feel significantly more responsive, with thrilling low-end surge, perfect for towing or fun on the open road

Pro Tip: Stick to moderate tunes if you want to preserve factory reliability. Push harder only if you’re ready to upgrade critical components.

Improving how your engine breathes is one of the most fundamental—and effective—performance upgrades. That’s why many diesel owners start with a cold air intake (CAI) and high-flow filter.

A performance CAI replaces the stock airbox and intake tubing with a larger, smoother, and less restrictive design, often enclosed in a heat-shielded or fully sealed airbox. This reduces intake resistance, allowing the turbo to pull in air more easily, especially under load.

Reduced Airflow Restriction:

Less turbulence and wider tubing allow faster, more efficient airflow to the turbocharger.

Lower Intake Temperatures:

Sealed or shielded airboxes pull cooler air from outside the engine bay, improving air density and combustion quality.

Improved Engine Response:

Better airflow improves throttle response and can yield small power gains, typically a few percentage points. Enthusiasts also enjoy the added turbo whistle in turbocharged applications.

S&B’s cold air intake systems are specifically engineered to minimize restriction while maintaining exceptional filtration:

Proven Gains:

Up to 31.7% more airflow over stock in applications like the Ford 6.7L Power Stroke.

Industry-Leading Filtration:

Uses eight-layer cotton gauze filters, ISO 5011-tested to trap over 99% of airborne dust—critical for protecting injectors, turbochargers, and engine internals.

Smart Design:

Vehicle-specific fit, sealed airboxes, and clear inspection lids for easy maintenance without removing the housing.

These systems are a smart first step that supports other mods like tuning, turbo upgrades, or exhaust systems, making the entire build more effective from the start.

Your engine can only make as much power as it can breathe. And one often-overlooked airflow bottleneck in turbo-diesel trucks is the intake elbow—the final bend between the intercooler and the intake manifold.

From the factory, these elbows are typically:

Narrow in diameter

Made with sharp bends or uneven internal surfaces

Constructed for minimizing cost, not performance

This restricts airflow just before it enters the engine, which increases turbo lag, raises exhaust gas temperatures (EGTs), and makes the engine work harder to produce the same power.

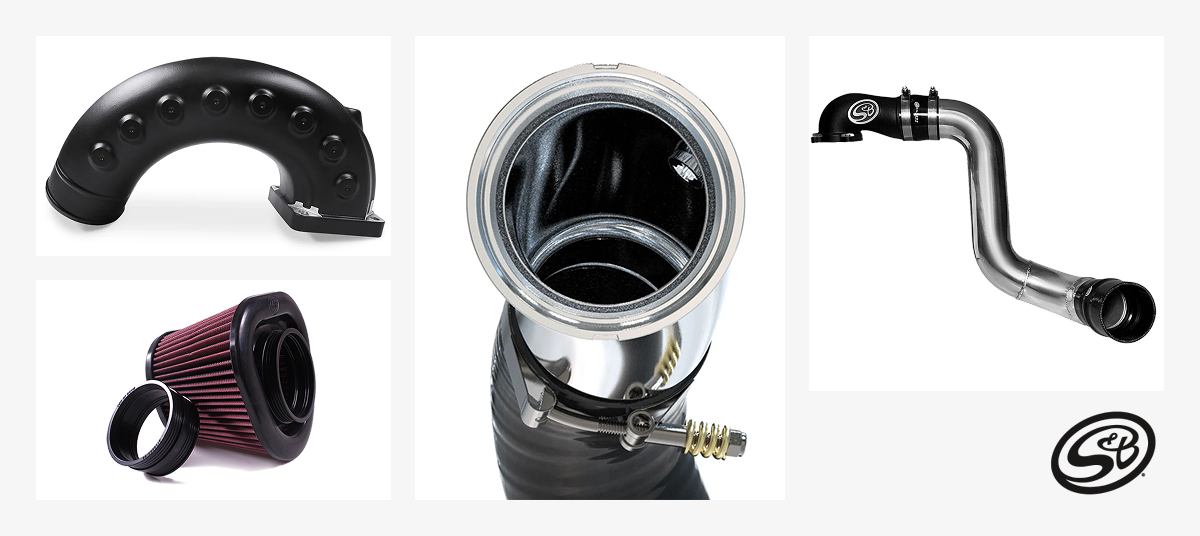

Upgrading to a performance intake elbow, such as those from S&B, reduces restriction and smooths airflow precisely where it matters most—between the boost and combustion.

S&B’s CNC-machined aluminum elbows are designed with high-flow geometry, smoother transitions, and a larger internal diameter. Independent ISO 5011 test results show:

Up to 43.6% more airflow than stock elbows

Faster turbo spool-up for improved throttle response

Lower EGTs, reducing heat-related stress on engine components

These improvements are especially valuable for tuned or heavily loaded trucks, where every degree of efficiency counts—whether you’re pulling a trailer uphill or laying down extra horsepower with a tune.

After your turbo compresses air, that air travels through the intercooler pipes—also known as charge pipes—on its way to the intercooler and ultimately into the engine. In this high-pressure zone, airflow speed and volume are critical. Yet factory intercooler pipes often present problems:

Narrow internal diameters and restrictive bends slow down airflow

Plastic construction (common in stock pipes) can weaken, crack, or blow off under higher boost pressure

Uneven inner surfaces create turbulence that disrupts consistent boost delivery

For stock trucks, this isn’t always an issue. But if you’re towing heavy, running a tune, or planning turbo upgrades, the stock piping can quickly become a weak link, both in terms of airflow and reliability.

Aftermarket charge pipes, like those from S&B, solve these problems with stronger materials and smoother airflow paths. Here's what makes the upgrade worthwhile:

Increased Durability:

Made from aluminum, S&B intercooler pipes are built to handle high boost pressure and extreme engine bay temperatures without flexing, cracking, or disconnecting under load.

Improved Airflow and Response:

Smooth, mandrel-bent designs minimize turbulence and pressure loss, ensuring the turbo’s boost is delivered efficiently to the engine. This leads to quicker throttle response and better turbo efficiency.

Built to Match Higher Boost:

If you're running upgraded turbos or tuning for more power, these pipes give you peace of mind that your system can hold boost consistently, especially important when towing or running high-performance software.

Pro Tip: Even if you’re not pushing a big boost, replacing brittle plastic factory pipes with robust metal ones is a smart move for long-term reliability, especially for trucks used in rugged or high-temperature environments.

S&B’s intercooler pipe kits are designed for direct-fit installation, offering a clean OEM-style fit with performance-grade hardware. They’re designed to work seamlessly with S&B intake elbows and cold air intake systems for a fully optimized airflow package.

S&B Ram Cummins Intercooler Pipes (Check specific year/application compatibility)

(Note: GM Duramax intercooler pipe kits may vary by year—consult S&B’s product finder for L5P/LML availability.)

Your engine is an air pump—so after improving how it breathes in, you’ll also want to improve how it breathes out. A freer-flowing exhaust system helps turbo-diesel engines expel exhaust gases more efficiently, reducing backpressure and exhaust gas temperatures (EGTs) in the process.

This leads to:

Improved turbo efficiency and faster spool-up

Lower operating temperatures, which protect engine and turbo longevity

A deeper, more aggressive exhaust tone that diesel enthusiasts love

While modern factory exhaust systems are fairly efficient, especially on newer trucks, the gains from aftermarket exhausts go beyond power. They're often about improving reliability, responsiveness, and driving feel, especially when towing or tuned.

For emissions-equipped trucks (2010+), the most common upgrade is a DPF-back exhaust. These systems:

Replace the piping and muffler after the Diesel Particulate Filter (DPF)

Are fully emissions-compliant and legal for road use

Offer better exhaust flow, reduced EGTs, and a more assertive tone

Can slightly improve throttle response, especially in tuned trucks

Note: DPF-back exhausts won’t produce huge power gains alone, but they do support better performance when combined with intake and tuning upgrades.

If your truck predates DPF systems, you may consider a turbo-back exhaust. These replace the entire exhaust system—from turbocharger outlet to tailpipe—for maximum flow.

Ideal for performance builds or off-road use trucks

Significantly reduces backpressure and improves spool-up

Must comply with local regulations if driven on-road

Legal Reminder: Tampering with emissions components (removing DPFs, EGRs, or SCR systems) is illegal in all states and can result in fines. Always verify local laws and choose compliant upgrades.

Upgrading your exhaust may not yield massive dyno numbers on its own, but it plays a key role in:

Supporting tuned engines and turbo upgrades

Keeping EGTs under control

Improving reliability and engine efficiency

Enhancing your truck’s sound and character

When paired with a cold air intake, intake elbow, and proper tuning, a quality exhaust system helps your diesel engine breathe better from end to end, especially important for towing or overtaking on the highway.

If you’ve already tuned your diesel and upgraded its airflow, a turbocharger upgrade is the natural next step. Turbo swaps or additions can yield massive performance gains, transforming how your truck pulls, climbs, and accelerates—especially under heavy load or in performance builds.

The beauty of turbo upgrades is the flexibility. From modest drop-in replacements to compound turbo setups that push four-digit horsepower, there’s an option for every goal and budget.

Ideal for daily drivers and towing builds, drop-in turbochargers retain stock fitment but offer better flow and efficiency:

Common for Power Stroke and Duramax

Often still use variable-geometry technology (VGT)

Improve top-end power and reduce EGTs

No major fabrication required; compatible with many factory components

These turbos offer a great blend of performance and reliability without sacrificing driveability.

Compound or twin-turbo setups pair two turbos to deliver boost across the entire RPM range:

Popular for Cummins builds

Use a smaller turbo for fast spool and a larger one for high-RPM airflow

Ideal for high-horsepower applications (e.g., sled pulls, drag racing, extreme towing)

The result? Quick low-end response and huge top-end flow—the best of both worlds.

Pro Tip: Compound systems require more complex installation and tuning but are a game-changer for serious power seekers.

A bigger or more efficient turbo moves more air, but your engine needs to keep up.

Fuel System Requirements:

Higher boost demands more fuel. Plan for upgraded injectors, lift pumps, and possibly high-pressure pump enhancements.

Supporting Mods:

Intercoolers, intake elbows, intercooler pipes, and exhaust systems must be capable of handling the increased airflow.

Proper ECU tuning is mandatory to manage the boost and fueling safely.

Without the right supporting upgrades, your new turbo won’t reach its full potential—or worse, it could damage your engine.

Turbo upgrades open the door to serious performance, whether you’re chasing 600 hp for towing or 1,000+ hp for competition. But more boost equals more responsibility—plan your build with the right airflow, fueling, and tuning in place.

Start small with a drop-in turbo for practical performance, or go big with a compound setup when you're ready to turn your diesel into a powerhouse.

In diesel performance, more air alone isn’t enough—you need the fuel to match. Whether you're tuning for more torque, towing heavy, or chasing dyno numbers, an upgraded fuel system ensures your engine receives the volume and pressure it needs to make reliable power.

Without proper fueling, your build will either hit a wall or risk running lean—putting your injectors, pistons, and turbo at risk.

Upgraded injectors deliver greater fuel volume per cycle, supporting higher horsepower builds:

Ideal for worn or underperforming stock injectors

Slightly larger nozzles can provide more fuel, but must be paired with airflow upgrades

May increase smoke or EGTs if not balanced with proper tuning and intake improvements

Best for: Moderate to high-power builds, especially when paired with upgraded turbos or aggressive tuning.

Lift pumps supply a consistent flow of diesel from the tank to the engine’s high-pressure pump, crucial when fueling demand increases.

Prevent fuel starvation, vapor lock, and air in the fuel lines—all common issues when the factory pump can't keep up

Often include filtration and water separation to extend the injector and pump life

Best for: Tuned or towing-focused trucks that demand consistent fuel pressure under load.

For extreme builds, even the stock high-pressure pump may become a bottleneck. Upgrading to a larger-capacity pump ensures:

Adequate rail pressure under heavy boost

Precise fuel delivery at high RPM

Compatibility with oversized injectors and high-boost turbos

This is typically done in high-horsepower or competition-level builds, but it is worth considering if your goals are 700+ hp or beyond.

Upgrading your fuel system ensures your diesel engine can take full advantage of every pound of boost and every degree of timing advance. The right combination of lift pumps, injectors, and high-pressure delivery can transform how your truck runs—cleaner, stronger, and more responsive.

Always pair fuel upgrades with airflow and tuning improvements to keep EGTs in check and maximize efficiency.

As you increase power through tuning, airflow upgrades, and bigger turbos, your engine and drivetrain are under more stress. Higher temperatures and internal pressures are natural side effects of added performance, but they must be managed to preserve reliability and avoid failure.

That’s why experienced diesel owners often turn to cooling and reinforcement upgrades to protect their investment, especially in tuned or heavily loaded trucks.

More horsepower means more heat, both in the engine and transmission. Upgraded radiators and coolers:

Improve coolant flow and thermal efficiency

Keep engine temps stable under towing or performance loads

Prevent transmission overheating, especially when towing up long grades or during stop-and-go hauling

These upgrades are often plug-and-play and make a significant difference in durability when pushing power beyond stock.

An auxiliary oil cooler helps control oil temperature during extended high-load situations, such as:

Heavy towing in hot weather

Long hill climbs or off-road use

Tuning with added boost or fuel

Cooler oil maintains viscosity and lubrication, reducing engine wear and extending service life.

If you’re building for serious power—especially on a Cummins or high-output Duramax—you’ll want to consider replacing factory head bolts with high-strength head studs.

Prevents head gasket failure under high cylinder pressure

Essential for builds running high boost, aggressive tuning, or larger turbos

Offers peace of mind in competition or heavy towing applications

Pro Tip: Head studs are a must-have for Cummins engines pushing well beyond stock torque. They're a one-time upgrade that can save your engine down the line.

When upgrading your diesel engine—whether it’s a Ford Power Stroke, GM Duramax, or Ram Cummins—achieving peak performance is only half the story. Real-world diesel builds demand a balanced approach, where horsepower and torque are matched by equal investments in reliability, comfort, and practicality. Engine modifications like upgraded turbos and tuning deliver impressive power gains, but sustained performance depends on careful attention to cooling, airflow, and structural support.

Critical supporting modifications—such as heavy-duty cooling systems, robust head studs, and reinforced intercooler pipes—help ensure your truck withstands the stress of added power, heavy towing, or rugged off-road use. Similarly, upgrades like high-capacity fuel tanks dramatically extend driving range and reduce downtime, while silicone body mounts provide a smoother, quieter ride and long-lasting durability, particularly crucial for expedition vehicles and overland rigs.

This is where brands like S&B excel. Renowned for industry-leading innovation, quality, and precision-engineered products, S&B designs diesel-specific upgrades that blend seamlessly into your build, whether you're pursuing maximum horsepower or dependable daily performance. Their OE-grade fitment, ISO-certified filtration standards, and exceptional Million Mile Warranty underscore a commitment to long-term reliability and worry-free ownership.

In the end, the best diesel build isn't solely about impressive numbers—it's about balancing raw power with practical usability. Choosing the right combination of supporting upgrades ensures your diesel engine not only performs reliably, comfortably, and efficiently for years to come. Explore S&B’s precision-engineered product lineup alongside other carefully selected performance mods to create a diesel powerhouse perfectly tailored to your needs. Your truck—and your driving experience—will thank you for it.